Quantum Heterostructures and Device Physics Lab @ LSU

Research Facilities

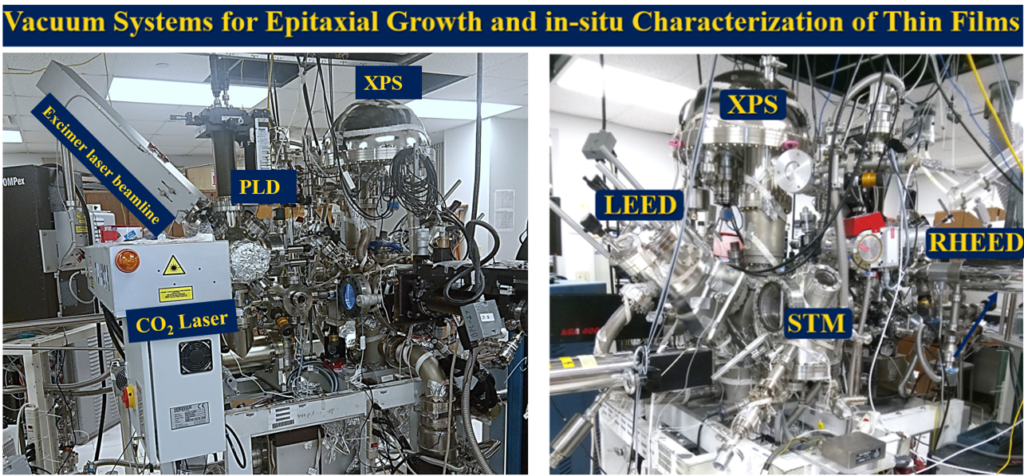

In our research lab, we employ a multicluster vacuum system architecture designed for the growth and characterization of high-quality thin films. Central to this setup is a Pulsed Laser Deposition (PLD) chamber, which enables the controlled synthesis of complex oxide materials. The system is integrated with multiple in-situ surface analysis tools, including Reflection High-Energy Electron Diffraction (RHEED), X-ray Photoemission Spectroscopy (XPS), Low Energy Electron Diffraction (LEED), and a Scanning Tunneling Microscope (STM). These capabilities allow real-time monitoring of film growth and detailed surface characterization without breaking vacuum. In the schematic/images below, the PLD chamber and various analysis modules are indicated on our multicluster vacuum system architecture.

Our multicluster vacuum system offers exceptional versatility for both the fabrication and analysis of thin films and heterostructures. It enables the growth of high-quality PLD films with atomic-layer precision, while also allowing for systematic in-situ characterization of the as-grown materials. Because all processes—from deposition to surface and structural analysis—are conducted under ultra-high vacuum, the films remain free from ambient exposure and surface contamination. This capability is crucial for investigating delicate interfacial or surface-driven phenomena that could be obscured or altered by atmospheric conditions.

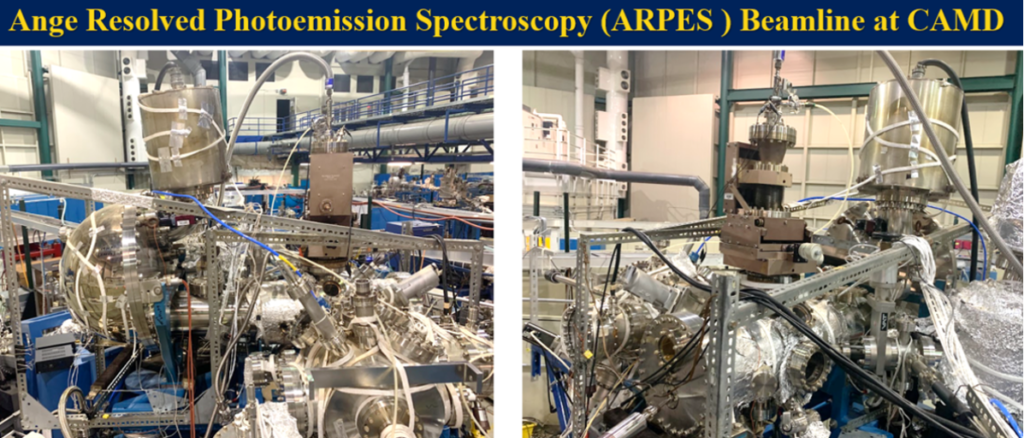

We routinely perform ARPES on both thin film and single crystal samples at our dedicated beamline at the LSU Center for Advanced Microstructures and Devices (CAMD), as well as at other national and international synchrotron radiation facilities. These studies are carried out in collaboration with partner institutions and utilize both laboratory-based ARPES systems and high-resolution synchrotron light sources. For thin film samples, our multicluster vacuum system is designed to interface with a vacuum suitcase, enabling ultra-high vacuum (UHV) transfer of samples over long distances. This feature ensures pristine sample surfaces are maintained throughout transport, allowing for in-situ ARPES characterization at external facilities without exposure to ambient conditions.